- BLOWER & VACUUM PUMP

HOME BLOWER & VACUUM PUMP

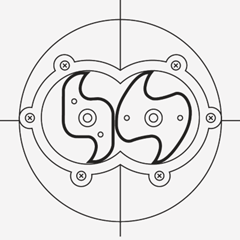

Description of Positive Displacement Blower Operation

Positive displacement blowers discharge air out into a pipe or hose in order to move materials. Rotors revolve and air is pulled into the inlet port, air is forced into tight areas between the rotors and casing then is forced to the outlet pipe (or hose). The term “positive displacement” comes from the fact that the volume of air doesn’t change within the blower but is displaced from one end to the other during operation.

Some of the most common industries that utilize positive displacement blowers include:

-

- Aquaculture

- Chemical

- Dairy

- Cement

- Oil & Gas

- Pulp & Paper

- Power Generation

- Dry Bulk

- Milling

- Plastics

- Wastewater Treatment

- Environmental

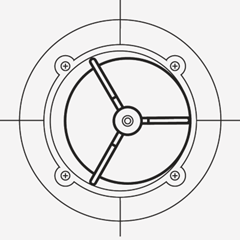

Our Industrial Vacuum Pumps

We design and manufacture a wide range of market leading industrial vacuum pumps for multiple types of application across many industries. Depending on your application and specific requirements we can select the correct vacuum pump for you without bias or limitation. We offer many types of vacuum technology including Rotary Vane, Lobe, Screw, Claw and Liquid Ring that cover flow rates and vacuum levels for most vacuum applications across the globe.

What is an oil-free vacuum pump?

An oil-free vacuum pump, also referred to an oil-less vacuum pump or dry running vacuum pump, is essentially a pump that does not use lubricants in the chamber to create a vacuum or cool the pump. In oil-lubricated machines lubrication is used a seal the vacuum chamber and cool the pump. Oil-free machines use other means to cool the machine during operation such as water or air cooling.